POWER ENHANCING DEVICE

Inventors: Mr.Raj Chowdhury, MS, Sumit Patankar, MS

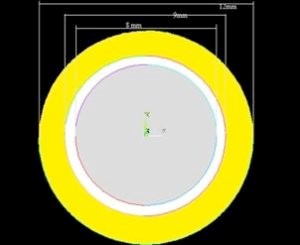

Fig.1

Fig.1 shows the plan view of the disc bender element.

The inner most concentric circular area in Fig. 1 shows the piezo element. The piezo element is

coated on top with silver which acts as one of the electrodes. The outermost concentric circular area in the figure (on which the piezo element is mounted) is made of brass and acts as the other electrode. Other common electrodes replacing silver and brass

can also work. The middle circular area shown in this top view is the insulation circumferencing the edge of the piezo material.

Most common insulation material can work to serve the purpose.

Fig.2

Fig. 2 shows the side view of the disc bender element and shows

the other dimensions and materials not shown in Fig.1.

These disc bender elements are placed between two layers of

patterned conducting foils. The conducting foil is patterned similar to the arrangement of the keys in a notebook or a cell

phone keypad (or other portable devices for which the set-up is being used), that is, the foil will have conducting material

deposited wherever the keys are placed in the device.

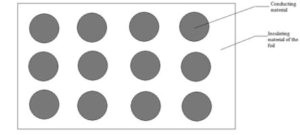

Fig.3

Fig.3 shows the top view of an approximate foil. The pattern shown in the

diagram is only an example and the actual pattern will depend on how the keys in the portable device are placed.

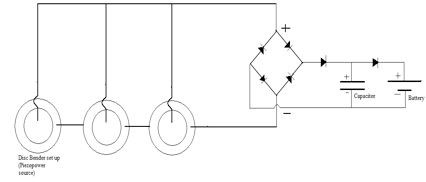

Fig.4

Fig. 4 shows the side view of two conducting foils between which the disc bender mounts. The top foil will touch the silver electrode and the

bottom foil will touch the brass electrode at all times. Instead of the conducting foils, electrical wires can also be used as

shown in Fig. 6.This is recommended to be tried first. These wires need to be soldered to the two electrodes

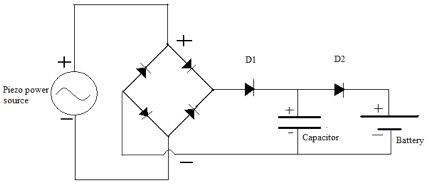

Fig.5

Fig. 5 shows the circuit diagram of the charging circuit. The AC-type power generated by the piezo element upon exertion of pressure by the user

is converted into DC power by the rectifier circuit shown in Fig. 5. This power charges the capacitor shown in the figure. The

capacitor used here has a capacitance of 1000 µF for charging a Li-ion battery set (of two) of a notebook. The capacitor

specification will vary depending on the portable device that is being charged. Pre-charge the capacitor before

typing.

When the instantaneous voltage of the capacitor exceeds the instantaneous voltage of the battery the capacitor

discharges into the battery charging the battery. The diodes D1 and D2 are used to limit the reverse flow of current from the

capacitor to the rest of the circuit and from the battery back to the capacitor respectively.